Thé Nikon CoolScan 9000EN, offering an innovative edition of Digital Glaciers®, had been the just device capable of removing dust and scrapes from Kodachromes untiI LaserSoft Imaging had developed a place of Kodachrome functions enabling a excellent range of readers to deal with Kodachromes.

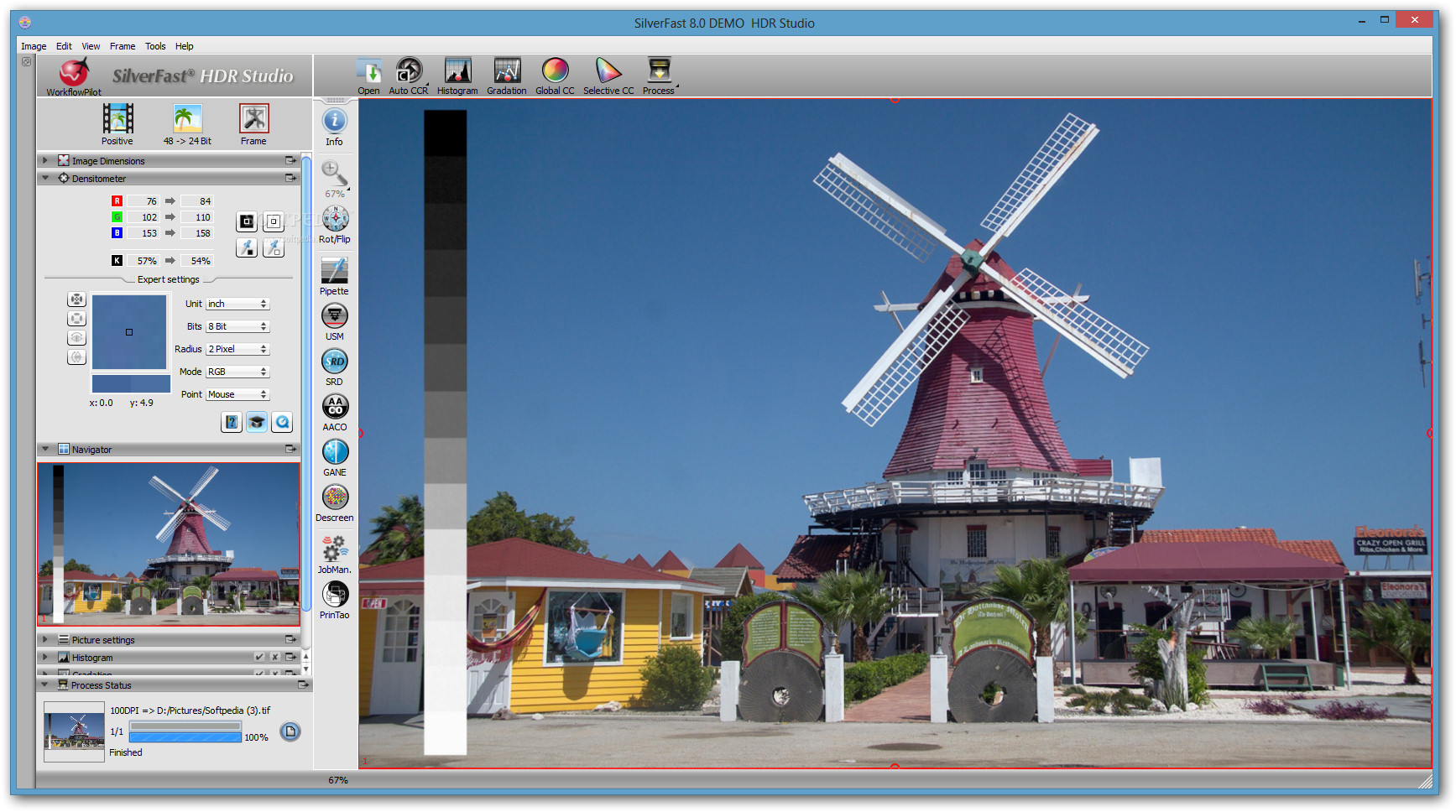

Setting srdx silverfast software#

Many scanner software produce blue casts and infrared dirt and nothing removal continually does not work out with Kodachromes.

SilverFast iSRD Kodachromé Kodachrome slides are very challenging to scan due to the silver halides this film material is containing. SilverFast SRDx is furthermore a excellent inclusion to SilverFast iSRD.īoth features can end up being optimally mixed to get rid of defects hardware- and software-baséd. Therefore, it can be a excellent tool for scanning devices that perform not feature any infrared functionality.

In contrast to iSRD it is definitely not making use of the infrared funnel. Selective modification by using face masks SilverFast iSRD ánd SilverFast SRDx SiIverFast SRDx is definitely a software-based device for removing dirt and scrapes, i.at the.

Setting srdx silverfast manual#

Manual handle of defect dimension that should become detected. Regular control of detection sensitivity. Goggles can become used on up to 4 various layers to limit the scrape removal impact on some areas of the image or to utilize different degrees of modifications.Īutomatic scuff removal. 1:1 preview mode SiIverFast iSRD in SiIverFast Ai Business 8 In SilverFast Ai Facilities 8, the iSRD device is extended by efficiency. Regular control of recognition sensitivity. In 1:1 preview mode, the results can be pre-evaluated in fine detail. You may completely believe in in the automatic setting or manually control the awareness of defect detection making use of a slider handle.

Setting srdx silverfast plus#

SiIverFast iSRD in SiIverFast SE 8 SE Plus 8 In SilverFast SE 8 and SE In addition 8, iSRD is certainly especially simple to make use of and reliable. After that the calculative dirt and scratch removal will take effect, just where the infrared route has discovered any defects without dropping any essential details. The image can be scanned two moments - the initial can be the regular RGB check out and the minute is usually the extra infrared check that captures flaws like dirt and scrapes only. ISRD makes use of this behavior as follows. Infrared light has a extremely broad wave-length, which allows it to move through film emulsion of downsides and slides without opposition, as compared to scuff marks and dirt particles that reflect it. It will be using the scanner‘s infrared funnel for defect recognition.

In contrast to regular methods SilverFast‘s dust and scratch removal features iSRD® is certainly based on the equipment. LaserSoft Imaging offers created a even more reliable solution for this issue. There are various software-based technology to eliminate these problems by thinking of the surrounding image details. Slides and problems always have got small dirt particles and small scrapes on them, even when handled very thoroughly.

0 kommentar(er)

0 kommentar(er)